MINERAL WATER INDUSTRY

We provide end-to-end solutions for setting up mineral water processing plants, from designing, installing, to commissioning state-of-the-art purification and bottling systems. We ensure a seamless and efficient setup, tailored to your specific business needs.

Trust us to transform your vision for a water treatment plant into a thriving, high-quality mineral water production facility.

WATER TREATMENT PROCESS

1

CHLORINE DOSING

2

PRESSURE SAND FILTER

3

ANTI SCALENT DOSING

4

ACTIVATED CARBON FILTER

5

MICRON BAG FILTER

6

MICRON CARTRIDGE FILTER

7

UV TREATMENT

8

REVERSE OSMOSIS

9

OZONIZATION

MACHINE REQUIREMENTS FOR A MINERAL WATER PLANT

STAGE 1- TREATMENT PLANT

STAGE 2- PET BLOWING MACHINE

STAGE 3- RINSING, FILLING & CAPPING

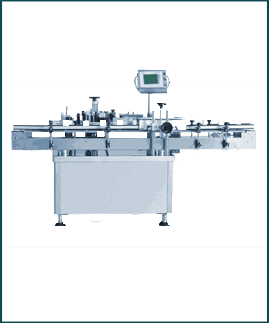

STAGE 4- LABELLING & BATCHCODING

STAGE 5- SECONDARY PACKAGING

Connect with us now to get Customised Solutions