RICE PROCESSING INDUSTRY

Rice is the most significant commercial crop, and milling is essential for converting it into a consumable product by removing the husk and bran layers. This industry is one of the oldest and most established agro-based businesses globally.

At Sunita Impex, we provide a comprehensive guidance through every step of process design, factory layout, and setup to optimize the cost-efficiency of your processing unit. While automation enhances quality and production output and reduces maintenance costs, our process designs are specifically tailored to augment productivity and efficiency. We provide complete solutions for your rice milling machine installation, whether you require a small, medium or large capacity. We manage the entire setup, from paddy separators to rice milling machines and end packaging systems. We offer solutions for setting up mini rice mills as well as large rice and paddy mills.

LINE DESIGN CRITERIA

Input Capacity

Form of Processing

Desired Output

Type of Packaging & Design

BASIC PROCESS FLOW

STAGE 1- PADDY CLEANER

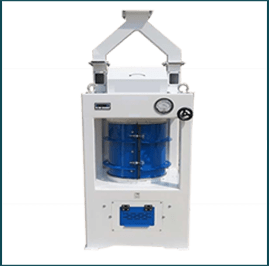

STAGE 2- DESTONER

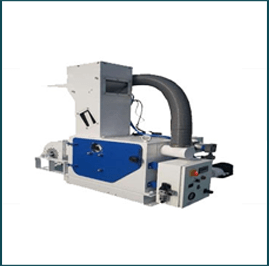

STAGE 3- SHELLER

STAGE 4- HUSK SEPERATOR

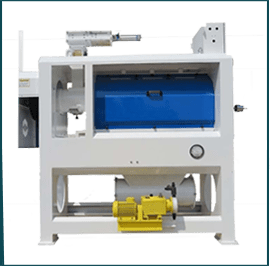

STAGE 5- PADDY SEPERATOR

STAGE 6- RICE WHITENER

STAGE 7- RICE POLISHER

STAGE 8- PLAN SIFTER

Connect with us now to get Customised Solutions